What are the installation precautions for a ball on off valve?

Leave a message

When it comes to industrial fluid control systems, ball on off valves play a crucial role. As a reputable supplier of ball on off valves, I understand the importance of proper installation to ensure the optimal performance and longevity of these valves. In this blog post, I will share some essential installation precautions for ball on off valves based on my years of experience in the industry.

1. Pre - installation Inspection

Before starting the installation process, a thorough inspection of the ball on off valve is necessary. First, check the valve's appearance for any visible damage, such as scratches, dents, or cracks on the valve body, ball, stem, or seals. Any physical damage can compromise the valve's integrity and lead to leakage or malfunction during operation.

Verify the valve's specifications, including its size, pressure rating, temperature rating, and connection type, against the requirements of the application. Using a valve with incorrect specifications can result in safety hazards and inefficient system performance. For example, if the pressure rating of the valve is lower than the system pressure, it may burst under high - pressure conditions.

Inspect the valve's internal components, such as the ball and the seats. The ball should rotate smoothly within the valve body, and the seats should be free from debris and damage. Clean the valve if necessary to remove any dirt, dust, or manufacturing residues that may affect its operation.

2. Site Preparation

The installation site should be carefully prepared to ensure a stable and safe environment for the ball on off valve. Select a location that is easily accessible for maintenance and operation. Avoid installing the valve in areas where it may be subject to excessive vibration, mechanical shock, or extreme environmental conditions, such as high - temperature areas near furnaces or areas prone to flooding.

Ensure that the piping system is clean and free from any foreign objects before installing the valve. Debris in the piping can enter the valve and cause damage to the internal components. Flush the piping system with an appropriate cleaning agent if needed.

The piping should be properly aligned to prevent misalignment stress on the valve. Misaligned piping can cause the valve to bind, leading to difficulty in operation and premature wear of the valve components. Use alignment tools to ensure that the piping flanges or threads are properly aligned with the valve connections.

3. Handling and Storage

When handling the ball on off valve, use proper lifting equipment and techniques to avoid dropping or damaging the valve. The valve should be lifted by its designated lifting points, if available. Avoid applying excessive force or impact to the valve during handling.

If the valve needs to be stored for a period before installation, store it in a dry, clean, and protected environment. Protect the valve from moisture, dust, and corrosive substances. Store the valve in an upright position to prevent damage to the internal components.

4. Installation Orientation

The correct installation orientation of the ball on off valve is critical for its proper operation. Most ball on off valves are designed for a specific flow direction, which is usually indicated by an arrow on the valve body. Install the valve in the correct flow direction to ensure efficient fluid control and prevent backflow.

For valves with a stem, the stem should be installed in a vertical or near - vertical position whenever possible. This helps to prevent the accumulation of dirt and debris in the stem packing area and ensures smooth operation of the valve. However, some valves may be designed for horizontal installation, so always refer to the manufacturer's instructions.

5. Connection Installation

There are different types of connections for ball on off valves, such as flanged connections, threaded connections, and welded connections. Each type of connection has its own installation requirements.

Flanged Connections

When installing a valve with flanged connections, ensure that the flange gaskets are in good condition and of the correct size and material for the application. Place the gasket between the valve flange and the piping flange, making sure it is centered and properly seated. Use the correct number and size of bolts, and tighten them evenly in a cross - pattern to ensure a uniform seal. Over - tightening the bolts can damage the gaskets and the valve flanges, while under - tightening can lead to leakage.

Threaded Connections

For threaded connections, use a suitable thread sealant to prevent leakage. Apply the thread sealant evenly on the male threads, following the manufacturer's instructions. Screw the valve into the piping slowly and carefully to avoid cross - threading. Tighten the connection to the recommended torque value using a suitable wrench.

Welded Connections

Welding a ball on off valve requires special skills and precautions. Before welding, remove any protective coatings or seals from the valve near the welding area. Use the correct welding process and parameters to ensure a strong and leak - free weld. After welding, inspect the weld for any defects, such as cracks or porosity, and perform any necessary post - weld heat treatment or cleaning.

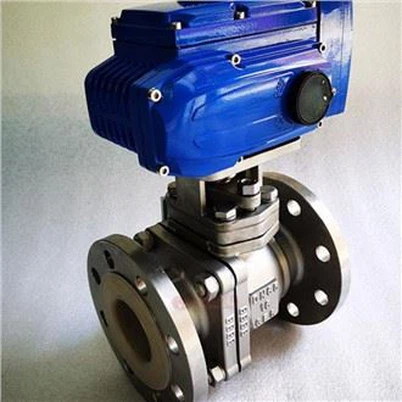

6. Actuator Installation (if applicable)

If the ball on off valve is equipped with an actuator, such as an electric or pneumatic actuator, proper installation of the actuator is essential. Follow the actuator manufacturer's instructions for installation and wiring.

Ensure that the actuator is properly aligned with the valve stem. Incorrect alignment can cause the actuator to malfunction or damage the valve stem. Connect the power supply or air supply to the actuator correctly, following all safety regulations.

Test the actuator to ensure that it can open and close the valve smoothly. Adjust the actuator settings, such as the opening and closing positions and the speed of operation, according to the requirements of the application.

7. Testing and Commissioning

After the installation is complete, conduct a thorough test of the ball on off valve. First, perform a visual inspection to ensure that all connections are tight and there are no visible signs of damage or misalignment.

Then, conduct a pressure test to check for leakage. Slowly increase the pressure in the system to the operating pressure and hold it for a sufficient period to detect any leaks. If a leak is detected, identify the source of the leak and take appropriate measures to repair it, such as tightening the connections or replacing the gaskets.

Finally, test the valve's operation by opening and closing it several times. Ensure that the valve can open and close fully and smoothly, and that the actuator (if applicable) responds correctly to the control signals.

As a leading supplier of ball on off valves, we offer a wide range of high - quality products, including the Electric Fluorine Lined Ball On Off Valve, Electric Three Way Ball Valve, and Pneumatic Three Way Ball Valve. Our valves are designed to meet the highest industry standards and are suitable for various applications.

If you are interested in our ball on off valves or need more information about installation and maintenance, please feel free to contact us for procurement and further discussions. We are committed to providing you with the best products and services to meet your industrial fluid control needs.

References

- Valve Handbook, Crane Co.

- Industrial Valves: Selection, Specification, and Installation, McGraw - Hill Professional.